Free consultation hotline18302431555

liaoningshengshenyangshihepingquhunhezhanxiangmanrongcun

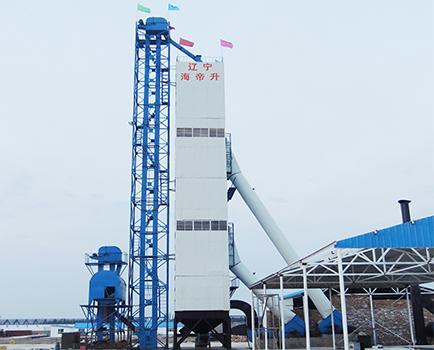

◆Application of smart drying technology: automatic materials loading, automatic circulation, automatic temperature control and automatic alarm.

◆Specialized drying: rice, corn, soybean, sorghum, barley, wheat and other corns.

tel:024-85856600 85856699

The air is used as the medium for cold drying. The drying technology such as mixed flow is applied to scientifically realize the grain drying processing, including preheating, heating, tempering and cooling, etc.

After dried up, the grain has uniform moisture, natural color and low crackle ratio.

The equipment is applicable to drying of corn, sorghum, rice, soybean, barley, wheat and their seeds.

The equipment heats grain through mixed flow of hot air, and the hot temperature is 120℃ -160℃. The grain is overturned through the angular box, so it has features of large heating area, uniform heating, stable process, continuous operation and costs saving.

The equipment is of combined structure and adopts heat insulation. The enclosure is provided with rain proofing, so it has high heat efficiency and saves energy. In the cold environment, the moisture elimination rate reaches 12-16%, so the equipment can eliminate the moisture of high-moisture grain to the safety moisture level.

Regulating devices are equipped for grain flow and hot air conveying positions of this equipment, and required drying indexes under different climate conditions are provided for grains in different categories and with different moisture.

An automatic monitoring and protection device is equipped to dynamically measure, observe and control the material level, grain temperature, air temperature and operation of matched auxiliary equipment to ensure the normal and safe operation.

The equipment is easy and convenient to install and occupies a small area.

|

Model |

Overall dimensions (mounting dimensions) (mm) |

Land occupation of equipment (㎡) |

Recommended site (㎡) |

Handling capacity (t) |

Moisture eliminate rate (%) |

Heat capacity (MW) |

Hot air pipe (pc) |

Capacitance (KW) |

Coal consumption (Ton) |

Equipment weight (Ton) |

|

HDS-L100Y-M |

2800×2200×18000 |

400 |

1000-1200 |

100 |

12-15 |

1.4 |

2 |

50 |

2-3 |

33 |

|

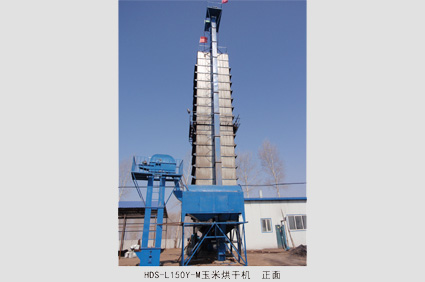

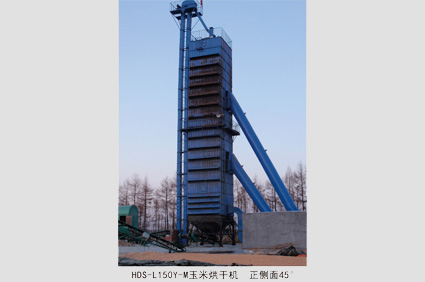

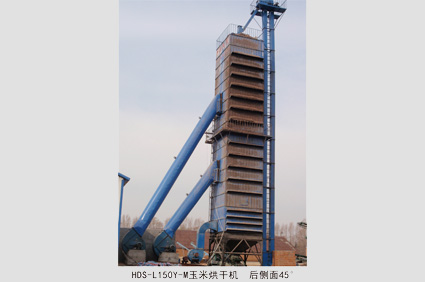

HDS-L150Y-M |

2800×2200×20000 |

400 |

1300-1500 |

150 |

12-15 |

2.1 |

2 |

71 |

4-5.5 |

35 |

|

HDS-L200Y-M |

3200×3200×22000 |

500 |

2200-3000 |

200 |

12-15 |

2.1 |

2 |

107 |

5-7 |

44 |

|

HDS-L300Y-M |

3700×3200×25000 |

550 |

3500-4500 |

300 |

12-15 |

4.2 |

3 |

148 |

10-12 |

70 |

|

HDS-L500Y-M |

4400×3700×30000 |

750 |

4500-6000 |

500 |

12-15 |

7 |

3 |

267 |

15-18 |

110 |

|

HDS-L600Y-M |

4400×3700×31000 |

750 |

4500-6000 |

600 |

12-15 |

8.4 |

3 |

280 |

16-19 |

120 |

|

HDS-L800Y-M |

5200×5200×28000 |

900 |

5000-7000 |

800 |

12-15 |

112 |

4 |

389 |

21-24 |

220 |

|

HDS-L1000Y-M |

5200×5200×33000 |

900 |

5000-7000 |

1000 |

12-15 |

112 |

4 |

464 |

25-28 |

240 |

The previous:HDS-L200Y-M

The next:The end